[Publication] A new hybrid additive process for manufacturing HTCC Al2O3-Mo

Additive manufacturing processes enable the production of increasingly complex 3D parts. What’s more, these digital processes can be used to manufacture ceramic/metallic parts with high dimensional resolution and interesting thermal, electrical and electronic properties for power electronics applications.

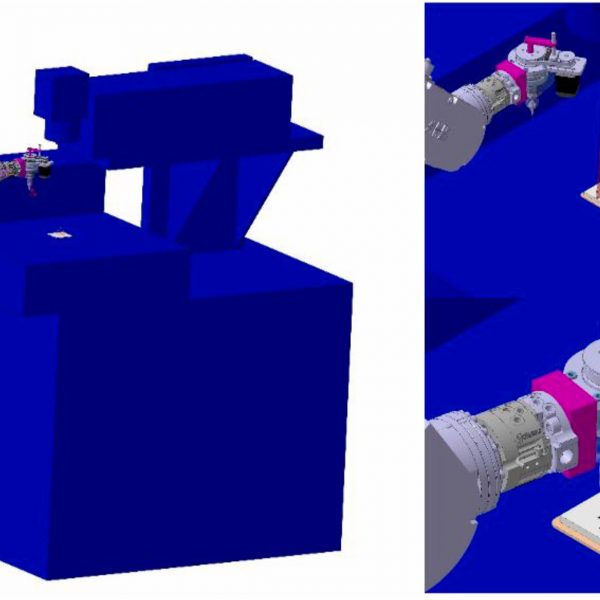

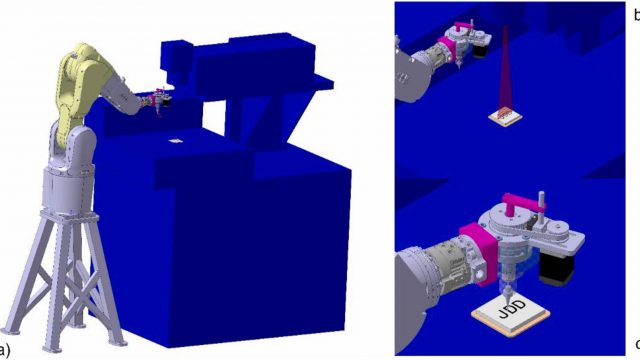

In this context, a hybrid additive machine has been developed to manufacture ceramic/metallic parts. This “INOV HTCC” machine, developed in partnership with 3D Ceram and CEA Cestas, combines two additive manufacturing processes: stereolithography and robocasting.

The originality of this process lies in its ability to simultaneously deposit ceramic and metal. This saves a considerable amount of time, reducing manufacturing time from 6 months to just one week, and enables more complex parts to be produced.

Indeed, using this hybrid process, the feasibility of HVDC components has been demonstrated by building dielectric alumina using stereolithography and a molybdenum conductive network using robocasting. A molybdenum-based metal formulation adapted to the process and enabling a highly conductive metal network to be obtained was developed. Co-delivery and co-sintering cycles were optimized to minimize residual carbon content and prevent molybdenum oxidation. The alumina/molybdenum interface was also observed to conclude that delamination between these two materials with different coefficients of thermal expansion (CTE) was possible. Sintered HTCC parts were characterized in the microwave range. The frequency responses deviate from the simulation due to a lack of dimensional accuracy of the metal lattice.

This work was carried out as part of a thesis co-funded by LABEX ∑-LIM. Collaboration between IRCER and XLIM enabled parallel work on the geometry and characterization of the components.

This work is also continuing with the ambition of improving the material, resolution and creating several components.

About the publication