[Publication] Machine learning-based prediction of compressive strength for limestone calcined clay cements

Cements based on calcined clays have great potential to significantly reduce the carbon footprint of the cement production sector. In particular, this new generation of cement has received particular attention from industry and researchers as a potential option for reducing CO2 emissions from the production of Ordinary Portland Cement (OPC) made from clinker (a cement constituent obtained by heat treatment of a mixture of around 80% limestone and 20% clay). Whereas the manufacture of Portland clinker requires heat treatment at around 1,450°C, the calcination of clay – which can replace part of the clinker – takes place at between 600 and 900°C, reducing energy consumption and CO2 emissions by 35 to 40%.

At the same time, exploiting the potential of calcined clay-based cements is limited by the inherent complexity of modeling their mechanical properties using empirical models. Indeed, the specific and dynamic behavior of cement hydration and the incomplete understanding of pozzolanic reactivity are not compatible with the usual calculation and modeling models. Moreover, over the past few decades, artificial intelligence methods such as machine learning have been used to predict material properties as a function of composition and synthesis parameters. The machine learning approach involves feeding an algorithm with input data to create models that optimize material properties. Machine learning has been applied in numerous studies focused on predicting the properties of cementitious materials, which is an emerging area of research. However, accurately predicting the engineering properties of this low-carbon cement remains complex due to the many parameters involved in the formulation and hardening processes, a scientific challenge that a team of researchers from IRCER and the XLIM Institute, with the support of LABEX ∑-LIM, has tackled.

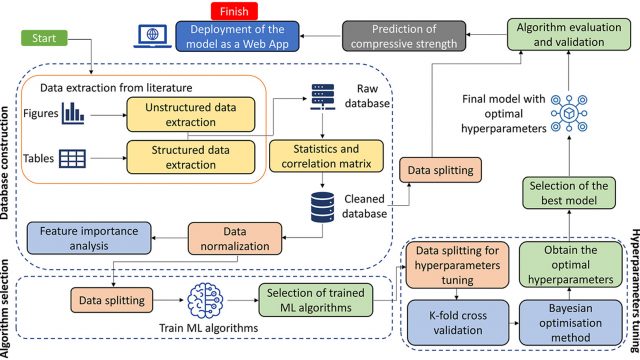

This work highlights the application of machine learning models to predict the compressive strength of calcined clay cement. Evaluation of seven supervised machine learning algorithms considering fourteen input features, (including percentages of clay, Portland cement and limestone, chemical composition expressed as reactivity ratios, clay calcination conditions and curing conditions) and training on a dataset of 323 mixes found that feature scaling is crucial for interpretable feature significance analysis. These results demonstrated that the trained model can accurately predict the compressive strength of calcined clay cement with an average absolute error of 2.5 MPa. The XGboost model, which emerged as the most accurate predictor of compressive strength among the models evaluated, revealed the significant influence of the alumina/silica ratio of clays on the compressive strength of calcined clay cements. In addition, interesting compositional ranges were identified for the raw materials, offering potential avenues for further optimization of these cements. This machine learning approach also aligned with experimental results published in the literature, showing a decrease in strength above 920°C, which is consistent with experimental results reported in the literature.

In conclusion, this groundbreaking work has validated the application of machine learning to predict the compressive strength of calcined clay cement, representing an important first step towards the design of potential new and optimized compositions. Future studies will focus on predicting the rheology and durability properties of calcined clay cement using machine learning techniques.

In addition, it is important to note that the carbon footprint of compositions predicted by the machine learning model requires a full life cycle assessment, which goes beyond the specific research question of this article.

Figure: Graphical summary of the prediction model for the compressive strength of limestone-based calcined clay cements, based on machine learning.

About the publication

Journal: Journal of Building Engineering – Volume 76

Date of publication: October 1, 2023

Authors: Yassine El Khessaimi ( XLIM, UMR 7252 CNRS/University of Limoges – IRCER, UMR CNRS 7315 CNRS/University of Limoges – Limoges, France), Youssef El Hafiane ( IRCER, UMR CNRS 7315 CNRS/University of Limoges – Limoges, France ), Agnès Smith ( IRCER, UMR CNRS 7315 CNRS/University of Limoges – Limoges, France ), Claire Peyratout ( IRCER, UMR CNRS 7315 CNRS/University of Limoges – Limoges, France ), Karim Tamine ( XLIM, UMR 7252 CNRS/University of Limoges – Limoges, France), Samir Adly ( XLIM, UMR 7252 CNRS/University of Limoges – Limoges, France ), Moulay Barkatou ( XLIM, UMR 7252 CNRS/University of Limoges )

Link: https://doi.org/10.1016/j.jobe.2023.107062