[Publication] Study of sintering mechanisms of Ca-doped yttrium aluminum garnet ceramics: From nanostructure to macroscopic behavior

Materials based on yttrium aluminum garnet (commonly known as YAG, chemical formula Y3Al5O12) are widely used in optical devices, thanks to the YAG matrix’s ability to incorporate numerous luminescent ions from the rare earth and transition metal families in solid solution. What’s more, thanks to their good thermal and mechanical properties, these materials can be used in highly demanding light-emitting devices operating in harsh environments. Since the 90s, several studies have demonstrated the possibility of manufacturing transparent YAG in the form of polycrystalline ceramics with an optical quality close to that of single crystals. Nevertheless, the optical quality of transparent ceramics depends on the absence of microstructural defects (residual pores, inclusions of secondary phases or impurities). For example, residual porosity in YAG ceramics must be less than 10-4% to achieve the efficiency of a solid-state laser incorporating a commercial single crystal. Consequently, rigorous control of all stages of the ceramic manufacturing process, including sintering, remains essential to achieve the high optical quality required for many applications. Among the strategies suitable for promoting densification and controlling the final microstructure of ceramics, the use of unconventional sintering methods such as HIP (Hot Isostatic Pressing) coupling the application of high temperatures with high Argon gas pressures remain well suited but very costly in terms of energy and resources. In comparison, the use of sintering additives based on abundant chemical elements (Si, Mg, Ca, Zr, etc.) is a very simple and inexpensive way of achieving this.

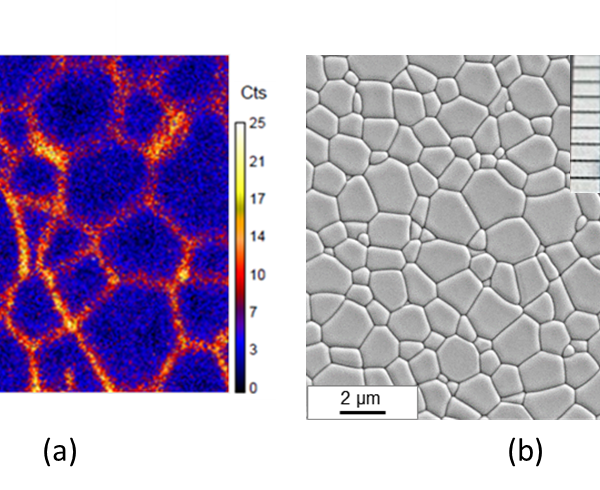

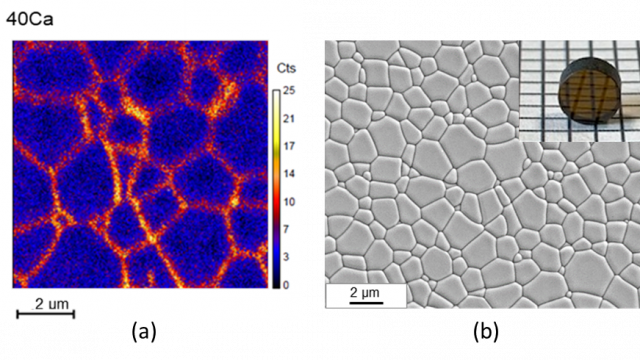

In this context, research carried out at the IRCER laboratory as part of Camille Perrière’s thesis (CIFRE DGA/CILAS) focused on the role of calcium in the sintering mechanisms of YAG ceramics. Structural and microstructural analyses revealed that calcium solubility was very limited, close to 650 ppm at 1700°C. Consequently, only levels below this value can be used to manufacture ceramics that are free of secondary phases and transparent. In addition, chemical analyses carried out at nanoscale by STEM and NanoSIMS showed calcium segregation at grain boundaries, associated with a decrease in densification and granular growth kinetics observed during sintering of this material. This result was explained by a solute drag mechanism, well documented for other ceramic systems. In the present case, this phenomenon is probably due to the segregation of complex structural defects, consisting of oxygen vacancies associated with calcium ions in solid solution, whose mobility at grain boundaries is very low. As a result, calcium appears to be a very effective sintering additive for limiting grain growth in YAG, thus avoiding the formation of intragranular porosity, which is a critical point for the manufacture of ceramics of very high optical quality. However, when used alone, calcium requires very high sintering temperatures, close to 1800°C, to ensure total densification of the material. Our work has shown that calcium acts in synergy with magnesium (YAG:Ca,Mg ceramics), which tends to lower the sintering temperature without negating the beneficial action of calcium in controlling the material’s microstructure. Ultimately, the results obtained will be very useful for the development of highly transparent YAG ceramics that can be used for the production of optical components.

As an example, this strategy has led to chromium-doped YAG ceramics incorporating calcium and magnesium as sintering additives (YAG:Cr,Ca,Mg), with saturable absorber properties and laser quality equivalent to commercial single crystals.

Figure: NanoSIMS chemical map of a sintered chromium-doped YAG sample containing 0.05% calcium as additive showing calcium segregation at grain boundaries (a) and corresponding SEM micrograph with a photograph of a transparent YAG:Cr,Ca,Mg ceramic insert.

About the publication

Journal of the European Ceramic Society

Volume 43, Issue 2

February 2023

Study of sintering mechanisms of Ca-doped yttrium aluminum garnet ceramics: From nanostructure to macroscopic behavior

By Camille Perrière, Rémy Boulesteix, Alexandre MaÎtre (Univ. Limoges, IRCER, UMR CNRS 7315, F-87068 Limoges, France) et Alain Jalocha (CILAS, F-45063 Orléans, France)

https://doi.org/10.1016/j.jeurceramsoc.2022.10.027