The ‘Glass material synthesis’ domain gives XLIM researchers, academics and industry access to high-performance measurement resources for all kind of glasses applied to optical fibres. Important equipments are available to realise such materials and processes.

Equipments available

Services available - contact us

– Glass working: Splicing of silica tubes, diamond cutting system for silica tubes …

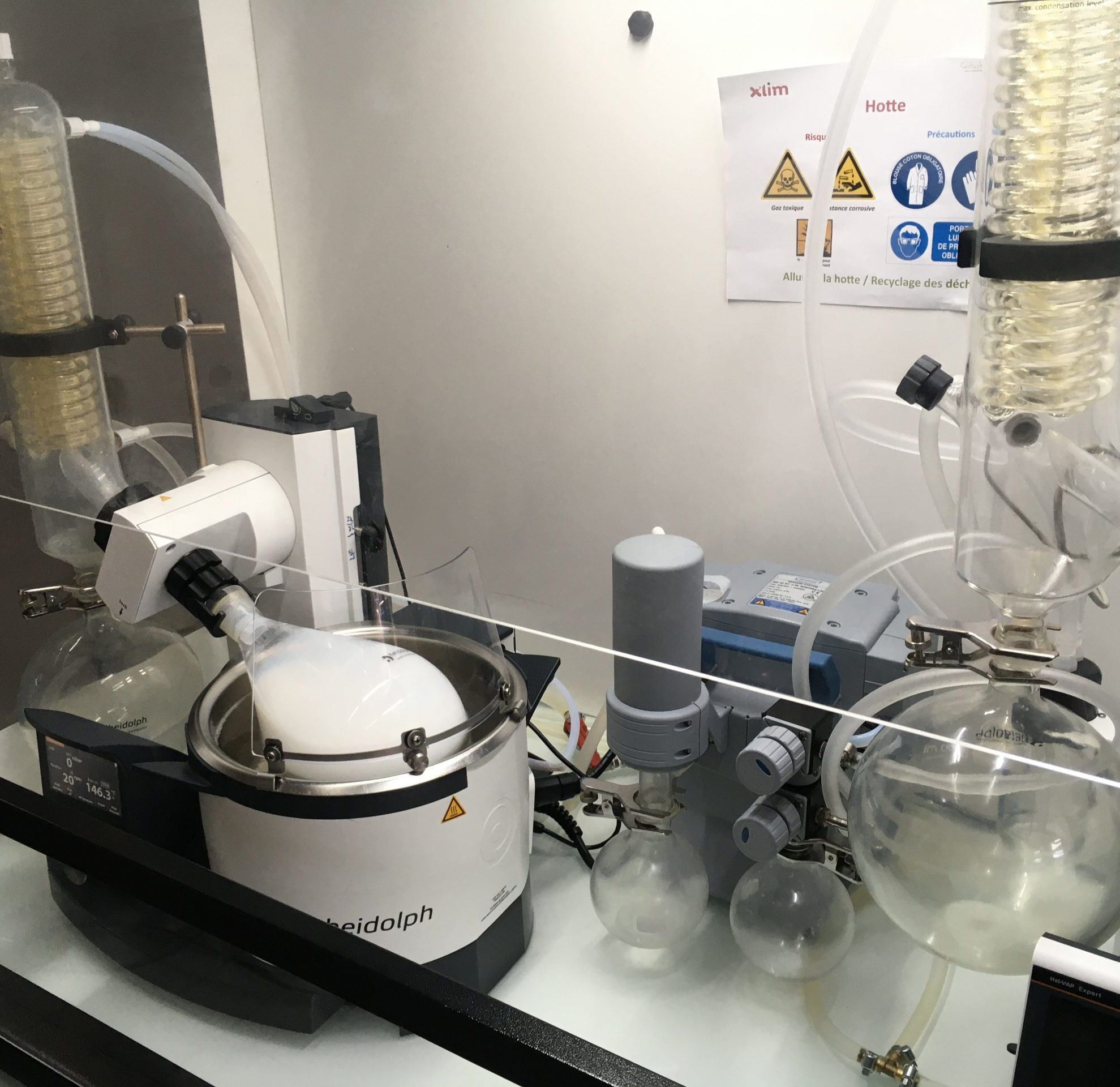

– Chemical way for glass production: Synthesis of glass from precursors, gas and/or heat treatment (C2F6 / O2 / He, and up to 2000°C)

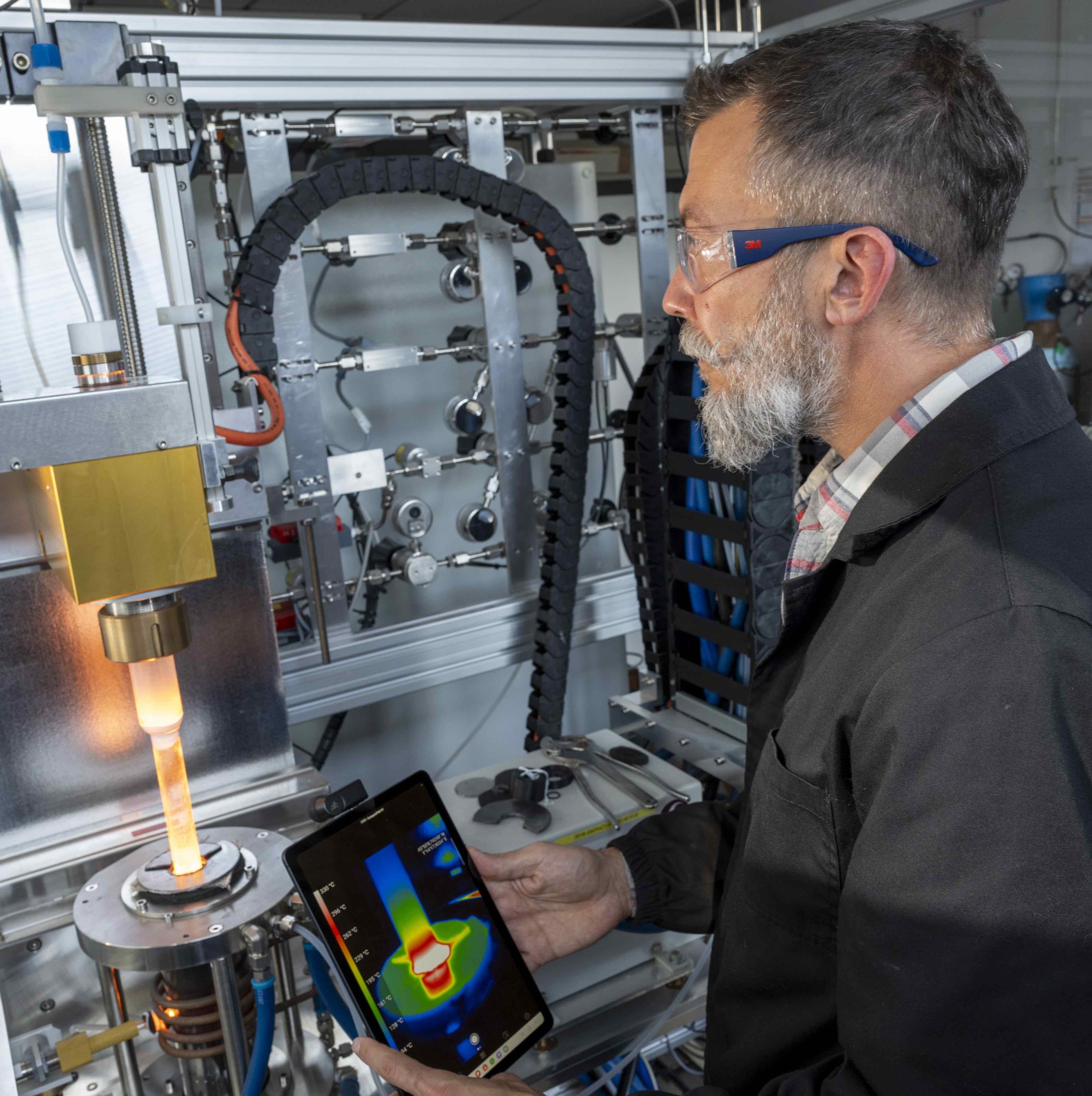

– Glass production by Melt Quenching technique: Melting up to 1700°C with or not gas treatment (C2F6 / O2 / He, and up to 2000°C)

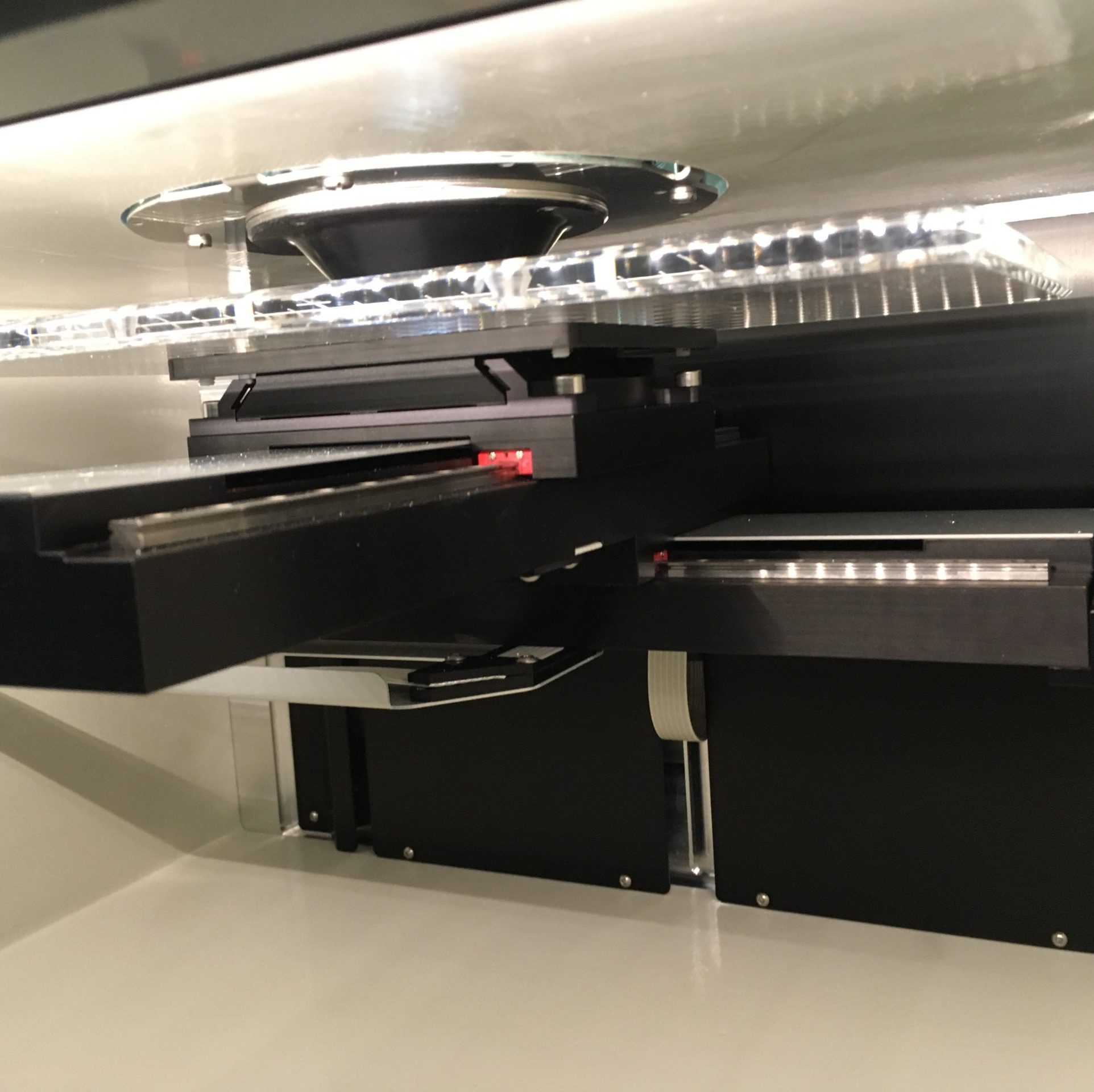

– Processes: Pressing Unit (up to 2000bars), Sintering Machine using inductive furnace (up to 2000°C). Assembling of capillaries for prefrom making – PCF

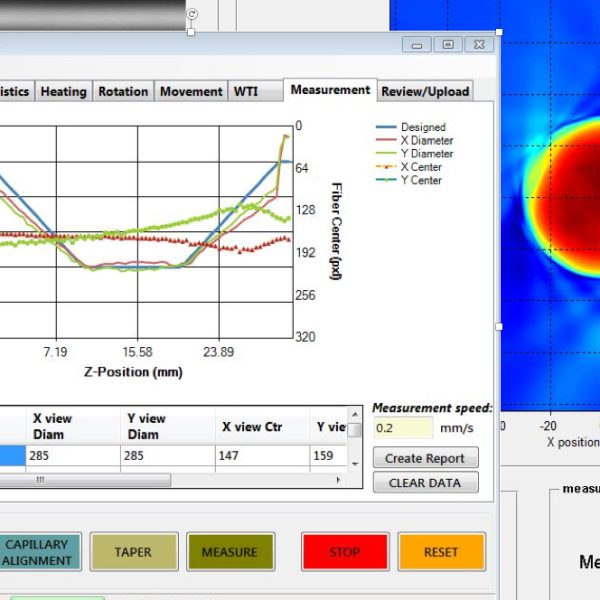

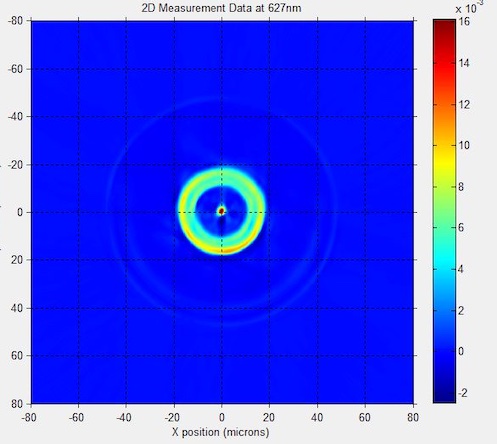

– Metrology on optical fibre and Post-processing : Refractive index profile measurement for fibres, stress measuring available, Rx measure on materials, CO2 Splicer for tapers, special splices …

Ressources

Videos, virtual tour, publications

Vidéo sur le Melt-Quenching

Cliquer pour accéder à la visite virtuelle du domaine ‘synthèse’

Publications de référence

https://doi.org/10.3390/s17061377

Multimaterial polarization maintaining optical fibers fabricated with the powder-in-tube technology