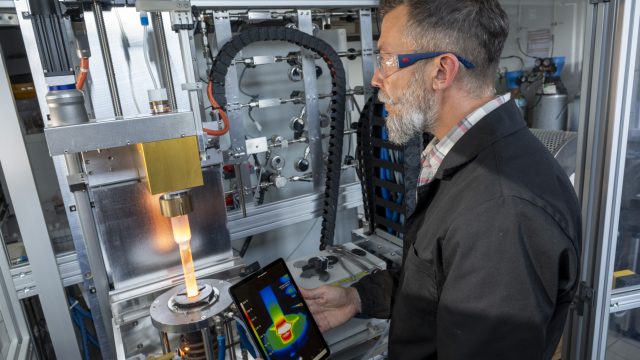

GB24_Processes for treatment, compaction and sintering

Following Glass synthesis (in powder way), materials have to be treated and shapd in order to produce a transparent rod, used at least to realiser the optical preform.

A first stage consists to purify with gas (O2, C2F6) at high temperature (up to 900°C) these materials.

The second is to produce a compact powder rod, usind a pressuring machine (up to 2000 bars).

Last step consists on sintering this rod at very high temperature (1550°C) to produce a full transparent piece of glass.

Some steps of machining are necessary to obtain a perfect surface roughness available in our glass workshop.

123, avenue Albert Thomas

XLIM - Faculté des Sciences et Techniques

87060 LIMOGES CEDEX

XLIM - Faculté des Sciences et Techniques

87060 LIMOGES CEDEX

université ouverte

source de réussites