Optical fibre – drawing

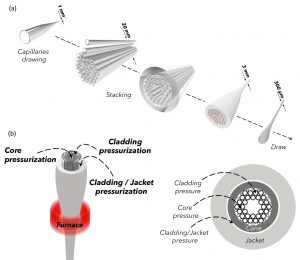

The XLIM research institute has recognised expertise in the field of so-called new-generation optical fibres. These fibres, which are produced using either ‘powder’ technology (see Synthesis section) or the ‘stack and draw’ method (manufacturing technique illustrated below), are fully mastered within the laboratory and form a fundamental part of the research work developed within two research teams: ‘Fibre Photonics‘ and ‘GPPMM‘ of XLIM.

This work uses the various fibres drawn within the platform as a tool and technological building block. A significant part of this work also concerns the optical fibre itself, with the search for state-of-the-art optical performance (loss levels, polarisation maintenance, modal content, etc.).

The fibre platform is part of the GIS – GRIFON, the CNRS national fibre platform, whose other partners are ICMCB (Bordeaux), ICB (Dijon), PhLAM (Lille), ILM (Lyon), LPMC (Nice) and ISCR (Rennes).

The various stages in the manufacture of optical fibres are all carried out on the platform’s drawing towers, which are equipped with systems (pressurisation, micro-positioning, etc.) that enable the various drawing parameters to be controlled with a high degree of precision and reproducibility. One of the main challenges is the need to control the thickness of the silica bridges in the fibre, which is extremely low – just a few hundred nanometres – allowing air-silica ratios of up to more than 96%.

The various members of the platform have expertise in the manufacture of a wide range of photonic crystal fibres, from solid-core to hollow-core.

Illustration of the stack-and-draw manufacturing technique.

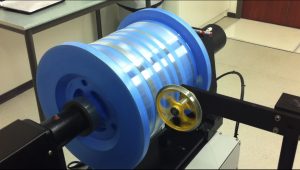

The technological resources comprise three fibre-drawing towers, two dedicated to photonic crystal fibre applications and one for more upstream developments.

The laboratory has also a horizontal lathe with synchronised jaws for mounting preforms, as well as a range of characterisation equipment: a fibre refractive index profile measurer, a chromatic dispersion measurement system, a scanning electron microscope and a range of more conventional characterisation systems (spectrum analysers, continuous and pulse laser sources, etc.).

– Drawing of fibres (preform not supplied), rods or capillaries (silica not supplied)

– Drawing of capillaries with supply of silica

– Complete drawing of microstructured fibres (with or without supply of silica)

– Complete drawing of “classic” fibres (with or without supply of silica)

– Drawing of low-temperature fibres (preform not supplied)

– Drawing of sol-gel fibres (with or without supply of silica)

– Fibre characterisation (SEM observation, loss measurements, index profile measurement).