Final restitution of the Climbing rope for research activities

On April 7 and 8, the posters of the first year master students were presented as part of the climbing rope for resaerch activities.

The goal was for the students to present their final work with their doctoral advisor in order to develop their experiences orally. The doctoral advisors were able to support the interest of the student’s work on his research.

The restitution closed the end of the courses and the common days for the students, before their departure in internship.

Focus on a research project: Shaping of bone substitutes for the local delivery of active molecules.

Project led by Meryem Lachhab, supervised by the PhD student Antoine Recorda and supervised by Chantal Damia at the Institute of Research on Ceramics – IRCER – Limoges

Why use bone substitutes ?

Bone tissue is constantly remodeling. This remodeling is necessary to maintain mechanical properties and to repair possible fractures. However, when bone regeneration becomes insufficient or in the case of an important tissue defect, the use of bone substitutes becomes necessary.

Bone substitutes (natural or synthetic) are used to fill critical bone defects in order to achieve bone consolidation and restoration of bone function.

What are they made of ?

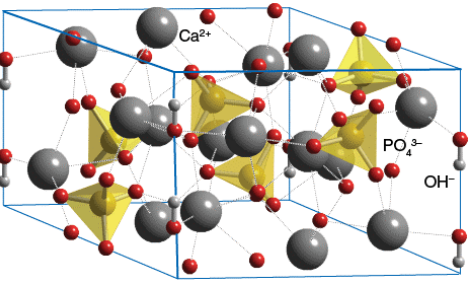

Porous phosphocalcic bioceramics are suitable as bone filling materials: they are biocompatible, bioactive and osteoconductive. It is interesting here to focus on the synthesis and development of stoichiometric hydroxyapatite ceramics. Indeed, its chemical composition is very close to that of the bone mineral matrix, and its crystallographic system is the same as that of natural hydroxyapatite crystals.

How to elaborate these bone substitutes ?

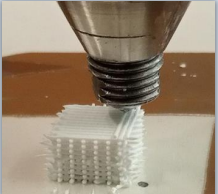

After the synthesis of HA powders, small architectures will be elaborated by superimposing paste filaments by a 3D printing method called robocasting (micro-extrusion). For this, the formulated paste must have specific physical characteristics. The macroporosity of the parts is directly linked to the process parameters and their microporosity is controlled during the consolidation of the parts (sintering).

What are the limitations of these architectures ?

However, these architectures have their limits since HA does not have antibacterial properties. To overcome these limitations, active molecules will be added to limit the risk of infection and ensure communication between the cells of the immune system and the bone cells. The behavior of these parts will be studied in a bioreactor to mimic physiological conditions and the release kinetics of these molecules will be studied.